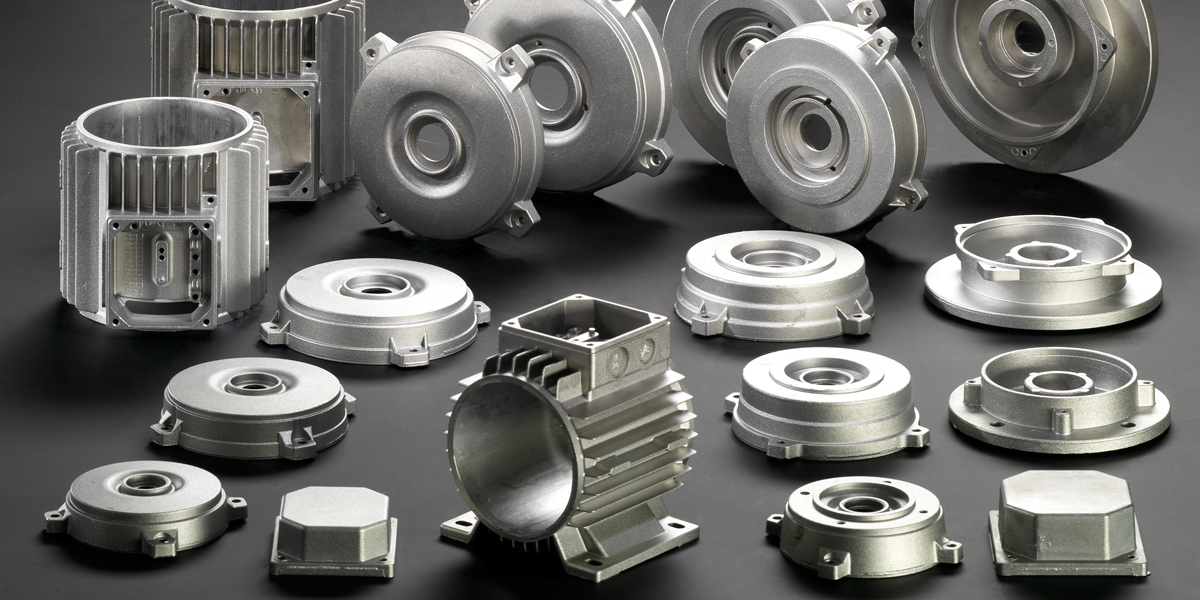

Diecasting has actually ended up being a vital procedure in Malaysia’s manufacturing industry, adding considerably to sectors like motor vehicle, electronics, and also durable goods. As an approach of generating complex metal parts along with higher preciseness, Diecasting enables suppliers to create light in weight however tough parts that meet international market specifications. The boosting requirement for high-quality steel products has set up Malaysia as a principal in the Diecasting market, along with various nearby and worldwide firms establishing sophisticated production establishments throughout the nation. Malaysian Diecasting companies take advantage of innovative innovation, reliable development techniques, and trained work to deliver high-performance metallic parts. The nation’s strategic area and also strong industrial framework make it an attractive center for Diecasting production, serving both domestic as well as global markets. With continuous innovations in materials and computerization, Malaysia’s Diecasting field is anticipated to grow and further enrich its own duty in the worldwide supply establishment.

Among the key causes for the development of Diecasting in Malaysia is its sturdy presence in the vehicle industry, where high-quality steel elements are actually important. The need for lightweight and fuel-efficient motor vehicles has actually raised the requirement for light weight aluminum as well as magnesium mineral die-cast parts, which supply excellent strength-to-weight ratios. Malaysian producers make a large range of die-cast vehicle parts, including engine components, gear box casings, and also building aspects, making sure cars continue to be both sturdy as well as energy-efficient. A lot of Malaysian Diecasting business follow rigorous global quality requirements, including ISO as well as IATF certifications, to meet the rigid demands of global automotive brand names. Along with the surge of electric motor vehicles (EVs), there is an even higher need for preciseness die-cast components, positioning Malaysia as a vital supplier within this advancing market. The nation’s commitment to innovation and also quality assurance makes sure that Malaysian-made die-cast parts stay very competitive on the world stage.

In addition to the auto industry, electronics as well as telecommunications markets likewise heavily depend on Diecasting for the manufacturing of accuracy components. Malaysia is actually recognized as a primary center for electronics creating, with many international firms putting together manufacturing plants in the nation. Die-cast metal components are actually widely used in consumer electronic devices, like smart devices, laptop computers, as well as home devices, as properly as in critical framework like system devices and also semiconductor equipment. The potential to make strongly elaborate sacrifice tight endurances makes die directing a perfect manufacturing strategy for these business. Malaysian Diecasting firms invest in stressful Diecasting (HPDC) as well as advanced molding methods to guarantee the manufacturing of regular, high-quality components. As international need for electronics proceeds to rise, Malaysia’s Diecasting field is well-positioned to supply essential parts that support the development of next-generation modern technology.

The customer items and industrial tools fields additionally help dramatically coming from Malaysia’s Diecasting functionalities. Products including family home appliances, power tools, and also industrial machines often call for intricate metallic housings, brackets, and also architectural elements that can hold up against heavy use. Pass away appointing offers a cost-effective service for making these parts in large volumes without risking on high quality. A lot of Malaysian Diecasting firms work very closely with item designers and also engineers to create individualized services that satisfy details sector needs. Advanced simulation software application and also automation technologies are actually increasingly being actually integrated in to the creation process to strengthen productivity and also lessen material misuse. By sustaining an equilibrium in between cost and efficiency, Malaysia’s Diecasting market carries on to assist various individual and industrial applications on an international range. For more information please Get More Information

Durability and ecological factors to consider are actually ending up being crucial consider Malaysia’s Diecasting industry, as manufacturers aim to minimize misuse and power intake. Several business are actually using ecological strategies such as utilizing recycled aluminum, improving production processes to reduce material wastefulness, and implementing energy-efficient machinery. Along with enhancing governing pressures and individual awareness, Malaysian Diecasting companies are paying attention to lasting manufacturing approaches without jeopardizing on item high quality. Some firms are actually additionally acquiring study as well as development to check out brand-new products and impressive casting methods that even more improve performance. Government initiatives supporting eco-friendly manufacturing and also Field 4.0 technologies have actually promoted Diecasting agencies to embrace intelligent production techniques. As sustainability becomes an expanding issue, Malaysia’s Diecasting market is actually conforming to international environmental specifications while sustaining its one-upmanship.

The future of Diecasting in Malaysia looks appealing, with ongoing expenditure in hands free operation, robotics, and fabricated cleverness (AI) to strengthen preciseness as well as performance. As business move toward even more complicated and lightweight materials, Malaysian producers are actually anticipated to increase their capacities to fulfill progressing market requirements. The integration of digital technologies, including real-time records tracking and also anticipating upkeep, will definitely better enrich manufacturing performance as well as premium management. With strong authorities assistance and also a strongly proficient labor force, Malaysia continues to be a leading destination for Diecasting production in Asia. As international supply establishments advance, Malaysian Diecasting business are actually well-positioned to supply high quality answers to markets worldwide, gluing their task as principals in the worldwide manufacturing yard.